About MANTA

MANTA Design (Scotland) Ltd wasn’t formed to market innovation, MDSL was extended as a platform for proof of design, generating feedback, testing in the wild, available for medical research, and responding to the data. There was a redesign, the original provided too large a supported area (before eBikes).

Our ‘Primary Objective’ was to find a safe, and appropriate “NEWCO” for assembly, marketing, sales, onwards. A unique, and significant, world-wide market opportunity. However, due to external demands, MDSL has continued supplying our latest iteration, not by marketing, but to support, and supply riders.

Things have taken off – as a one-man, plus assistants, ‘cottage industry’ – we can endure, until production, and marketing is relocated in “NEOMANTA”, we are accepting pre-orders (i.e., avoiding ‘Kickstarter’), until current the recent trench of customers is supplied. Any lead-time will reduce, and disappear.

Our Primary Objective was delayed by external forces (Jon’s written an instructive book for innovators about avoiding entrepreneurial pitfalls). Despite this distraction, Jon has implemented upgrades, and options, to be released ASAP, everything is backwards compatible, or an add-on.

We’re seeking local entrepreneurs initially, this being MANTA’s spiritual home, and to provide local employment. Whatever works.

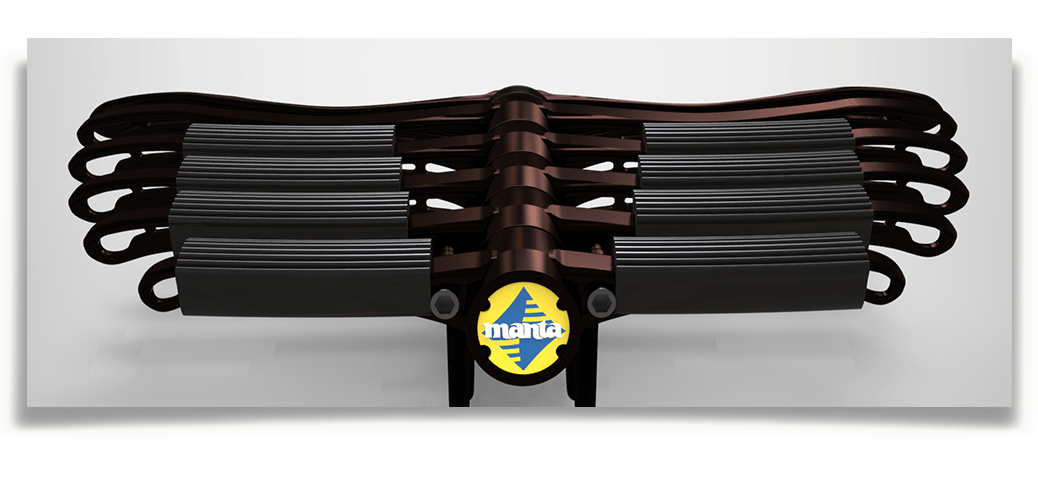

Unique design

In Scotland

Jonathan Catling (Jon), is an engineer, builder, project manager, and sculptor. He was busy avoiding car ownership in Cambridge, where he was born. He always loved the freedom of cycling, and expanded into motorcycles. Cycles, mainly, were perfect for Cambridge life (pubs, river), flexible, cheap, good fun, supremely efficient for the city, and beyond.

In the late 80’s Jon was working for an agency, electronic test engineering of various sorts, he says he “enjoyed flexibility, diversity, good pay, it was great. Work dried up for us all in Cambridge, imagine!” An opportunity to work on Skye, an increasing obsession, led to a job building stone paths up the Cuillin (hills), he loved it, but was working with meningitis without realising.

Jon swapped waterproofs for CAD

In contrast to bicycle efficiency and the development of modern bicycles, cycle seating has remained much the same since the bicycle’s inception.

Pain is a body’s way of saying something isn’t right. It affects endurance and enjoyment. You think you get used to it, but you go numb, and this isn’t good. Eventually, parts that should be soft, become calloused.

The Manta is unique in increasing arterial bloodflow during cycling.

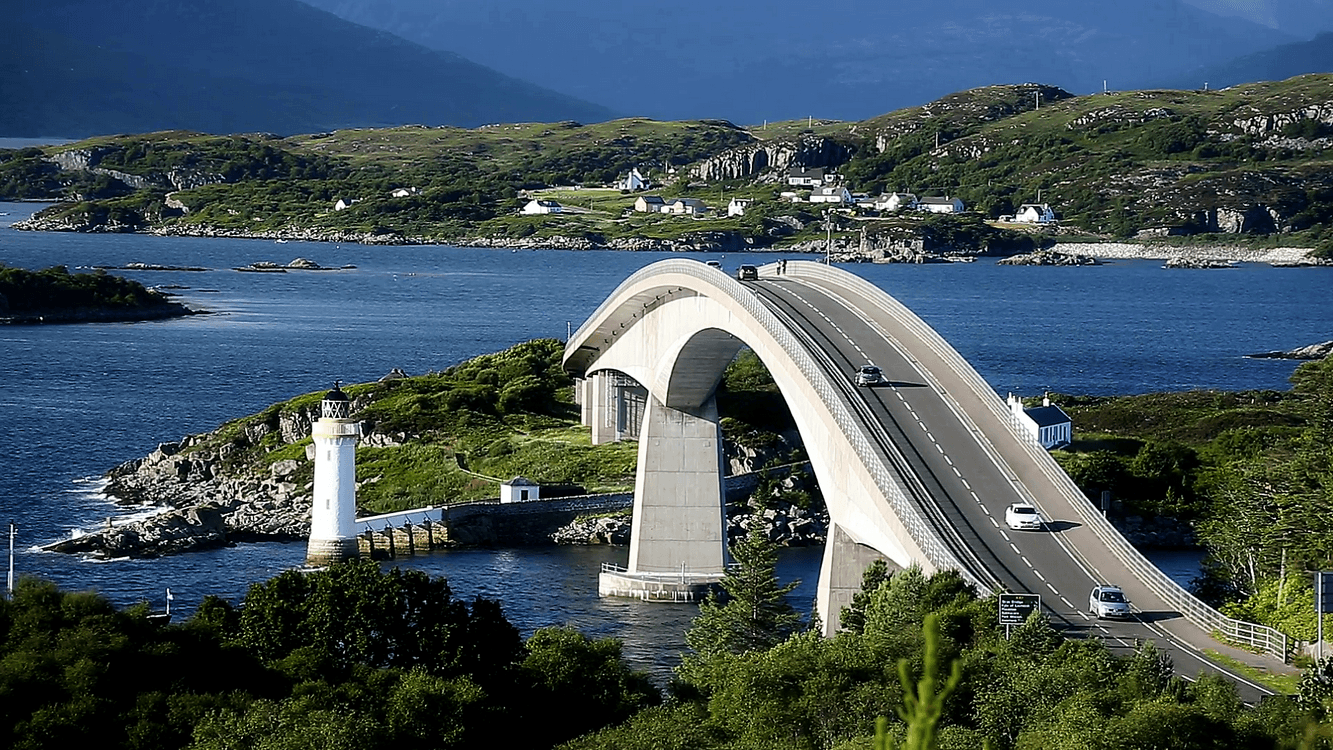

Many prototypes were visualized, trialled, and tested on the Isle of Skye, NW Highlands, from about 1999-2003.

Jon had been cycling the potholed, hilly, twisty, tough Skye roads, enjoying open spaces and quiet. An excellent mind-space, with forestry tracks, IPR security-speaking, it was safe from view (outside the tourist season).

“Cycling was a passion. I was aware of how pain impacts endurance; the legs are good for more miles, the backside just isn’t.”

“On my favourite island, in an old stone, fisherman’s cottage, I found myself with time, and a totally tranquil space…”

“…as it turned out, having plenty of time was just as well, the design required a huge amount of development. Many abandoned prototypes later, one leapt out, while testing another, this was clearly effective, deserved full focus at last. The final geometry of the design was eventually taken to the mainland, to seek industry and cycling expertise.”

It has complex kinetics, making manufacture a challenge itself, but it was clearly the way ahead.

“Manufacturing development was very involved due to the complexity of forms required for the precise articulation, needed to follow a seated human form precisely, crucially, while in motion. As soon as it did, this was a ‘Eureka’ moment.”

Jon had an opportunity, unplanned free time, to focus on cycling's fundamental problem Existing comfort saddles are compromised, they lack the form and function to support a human body as it should be supported, naturally.

Movement is restricted when adding width conventionally, leading to chaffing, and nerve compression, even if the pudendal arteries are not affected by a saddle ‘nose’, pressure moves elsewhere, often in other critical areas It has been a tradeoff. The support area of ‘conventional comfort’ seats is little better than a conventionally narrow sports seat in use – which is preferable to wider padding. As we mentioned, that needed changing somehow.

“The design’s priority wasn’t just to provide a perception of comfort – an initially soft feel – it was to provide an absence of the causes of discomfort. With zero peak pressures, and an even distribution, over a far larger area, none in the pudendal zone.”

The parameters were to maximise support, with no loss of motion in the supported body.

Jon contacted BBC Tomorrow’s World, who had an open innovations programme, he was advised not to go public with a design, they saw it as having commercial potential. It was suggested, a patent must be applied for.

“Almost a year was spent searching patents, then talking to innovation investors, NESTA, about prototype market trials, this seemed a great cost for prototypes, for one day’s feedback, at a venue somewhere.”

“My brother, Paul and I (and his business experience), were obliged to form a limited company as part of NESTA negotiations.”

“We decided to go ahead with development for manufacture, straight to public trials, based on a product, trusting real-world cyclist’s feedback, rather than a hall full of folk off the street.”

“This was achieved with assistance of friends, riders, manufacturing experts, especially DuPont, including the final prototype, then Velo Ent., carbon fibre specialist Lola, and a successful six months prototype trial with Décathlon, Lille.

Rather than the expense, and distance of working in Taiwan, we took the opportunity to work with DuPont, again, alongside Protomould in Fife, introduced by Edinburgh Business Gateway. We met Bill Scott, Protomould’s owner, and it was clear he was perfect to work with. He was to produce a final, high quality tooling, and the early production runs. These processes, took about eight years.”

During this early development, and proof-of-concept, Jon’s cottage paid for patents, and secured the design. Beyond that, Jon and Paul’s family [bravely] stepped in to keep the family business independent. Scary, but all involved were confident in the design, it’s having passed enough, and varied trials.

“Motivated by the contrasting experiences in use, and increasing evidence of damage caused by conventional nosed saddles. Feedback from early takers was impressive, reassurance”.

“Conventional saddle design has barely changed from the very beginnings of the bicycle, the ability to support the human anatomy has become less, in real terms. I think we just changed that.” – Jon

Ma & Pa, our earliest Manta investorsThe design, and our independent manufacturing, is their legacy...All @MDSL love cycles, as a thing, they’re quite as perfect, as machines can be, we liked the contrast in a cute quote from Steve Jobs: “I read a study that measured the efficiency of locomotion for various species… the Condor used the least energy to move a kilometre. Humans came in with a rather less impressive showing, about a third of the way down the list. But then someone at Scientific American had the insight to test the efficiency for a man on a bicycle – a man on a bicycle blew the Condor away” – reasonably fit cyclists can ride about twice as far as a horse’s average 50miles/80km a day.

Each Manta began its travels crossing Skye's bridge to the mainland, now we have a base right by here - ¡Buen viaje!

Coop on the mount, (Jon's stairs nemesis), from the ferry slipway, onto The Bridge - ¡Buen viaje!

Manta Design Scotland Ltd Reg. SC0355993

3 Duncan MacPherson Court

Main Street

Kyle of Lochalsh

Ross-Shire

IV40 8AY

Includes: Unified Sport, Evolve Cycle, MantaCycles

Terms & Conditions & Privacy Policy